Iot Sensors In Predictive Maintenance

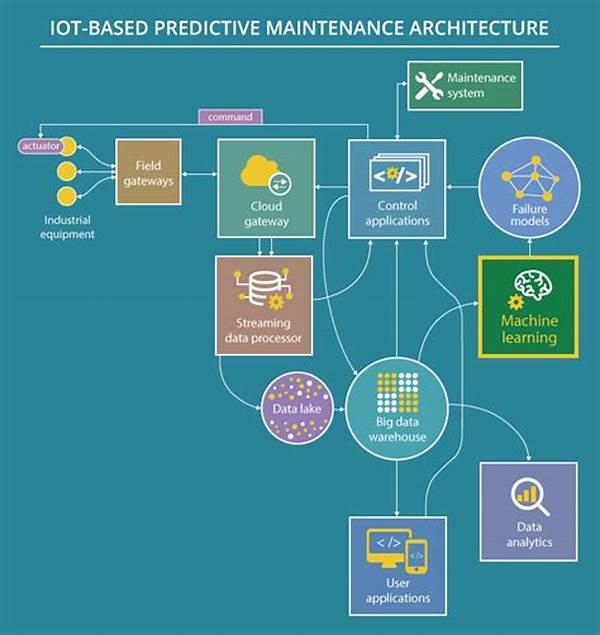

The integration of IoT sensors in predictive maintenance has revolutionized the way industries manage their equipment and machinery. By leveraging the capabilities of IoT technology, businesses can now transition from reactive to proactive maintenance strategies, significantly reducing downtime and improving operational efficiency. IoT sensors in predictive maintenance provide real-time data on equipment performance, enabling timely interventions and effective decision-making processes. This technological advancement not only optimizes resources but also extends the lifespan of critical assets, ensuring sustained productivity and cost-effectiveness.

Read Now : Easily Find Ev6 Chargers

The Impact of IoT Sensors in Predictive Maintenance

IoT sensors in predictive maintenance? Oh, they’re like the superheroes of the industrial world, swooping in just in time to save the day. Imagine having a sixth sense for when your machines are about to throw a fit. That’s what these sensors do, giving you the lowdown on every little hiccup before it turns into a monstrous breakdown. With IoT sensors in predictive maintenance, it’s all about keeping things chill and eliminating those annoying surprise malfunctions that throw a wrench in your operations. Whether it’s detecting vibrations, temperature fluctuations, or unusual sound patterns, these sensors are your ticket to a smoother ride. It’s like having a crystal ball, but way cooler and much more reliable.

The Magic Behind IoT Sensors in Predictive Maintenance

Alright, let’s break it down real quick—those IoT sensors in predictive maintenance? They’re like the ultimate gossip buddies for your machines. They spill the beans on everything happening inside those mechanical giants. No more guessing games about what’s gonna go wrong. With IoT sensors in predictive maintenance, you catch the drama before it happens. You know that one friend who’s always in the loop? Yep, that’s what these sensors are to your factory floor. Keepin’ it real and keepin’ ya informed, 24/7.

1. IoT sensors are the eyes and ears for machines.

2. Say goodbye to unexpected breakdowns, bro.

3. It’s like a sneak peek into the future, dude.

4. Your maintenance crew’s gonna love it.

5. Chill, ’cause the sensors got your back.

Leveraging Data from IoT Sensors in Predictive Maintenance

So, picture this: You’re sitting there, sipping your morning coffee, and bam! Your phone buzzes with a notification. No, it ain’t your buddy texting. It’s your machinery whispering sweet nothings through the magic of IoT sensors in predictive maintenance. These babies are like the backstage pass to your equipment’s heart. They gather all that juicy data—temperature, pressure, vibration, you name it. Then, they hit you with the lowdown, letting you know if anything’s acting shady. It’s like having a personal assistant who’s got the 411 on every little thing happening with your machinery. Whether you’re a tech-savvy guru or just trying to keep things running smoothly, IoT sensors in predictive maintenance are your new best friend.

Now, forget about the days of scrambling when something goes haywire. With this kind of heads-up, you can plan like a boss. Oh, and did I mention it’s a total game-changer for your maintenance crew? Fewer fire drills and more chill vibes as they handle only what’s necessary. Keep your systems running like a well-oiled machine—literally. IoT sensors in predictive maintenance don’t just optimize your maintenance game; they elevate it to a whole new level.

Exploring the Variety of IoT Sensors in Predictive Maintenance

Exploring IoT sensors in predictive maintenance is like diving into a treasure trove of possibilities. These sensors come in all shapes and sizes, each with their own mission and purpose. Whether it’s a tiny sensor detecting temperature changes or a heavy-duty one gauging pressure differences, there’s something in the toolbox for every need. They work together like a dream team, covering each other’s backs and making sure nothing slips through the cracks.

1. Vibration sensors sense when things are shaky.

2. Temperature sensors keep tabs on the heat.

3. Pressure sensors gauge those intense moments.

Read Now : Quattroporte Navigation System Installation Instructions

4. Humidity sensors know when things get a bit damp.

5. Acoustic sensors listen for eerie sounds.

6. Optical sensors have that keen eye.

7. Infrared sensors are all about heat signatures.

8. Magnetic sensors have a pull for magnetic fields.

9. Gas sensors sniff out any leaks.

10. Proximity sensors are all about keeping their distance.

Unlocking the Future with IoT Sensors in Predictive Maintenance

Yo, have you ever thought about how far tech has come? IoT sensors in predictive maintenance, man, they’re not just a part of the future—they ARE the future! Think about the crazy potential of these gadgets. The sensors are catching those red flags before they even become problems. It’s like everyone else is playing checkers, while you’re out here playing 3D chess. You know what I’m saying? Every piece of data collected is like a gold nugget, with insights that have the power to transform entire industries.

First off, it’s a huge win for the dough, saving companies mega bucks by preventing costly breakdowns and extending the life of assets. Second, hello to efficiency! With less downtime, everything runs smoother than my grandma’s homemade gravy. And let’s not forget the cool factor—being able to strut because your maintenance game is tight. IoT sensors in predictive maintenance really flip the script, making it so industrial operations aren’t just surviving, but absolutely thriving.

IoT Sensors in Predictive Maintenance: A Sneak Peek

Yo, let’s talk about what makes IoT sensors in predictive maintenance a total game-changer. First off, these sensors are like the Bat-Signal for maintenance crews. They’re throwing up alerts faster than Twitter on a bad day. Second, the data game is strong. We’re talking analytics that are on-point, making your equipment run smoother than a new pair of sneakers. Each sensor is like Sherlock Holmes, piecing together clues to stop failures in their tracks. They’re aligning operations so that the workflow stays as smooth as peanut butter.

IoT sensors in predictive maintenance are also about waving goodbye to those scrambling moments when something suddenly breaks down. Instead, you’re dancing in a world of precision and proactivity. So next time someone asks you about IoT sensors, tell ’em it’s all about the smart game. Playing it safe and shifting the focus from reactive panic to smooth, coordinated moves. Whether you’re a tech wizard or just dipping your toes into the world of IoT, one thing’s for sure—these sensors have your back, keeping everything running like clockwork.