“structural Integrity In Lightweight Vehicles”

Understanding Structural Integrity in Lightweight Vehicles

When it comes to the structural integrity in lightweight vehicles, it’s a big deal. Imagine cruising down the highway in a ride that’s sleek and light, but beneath that cool exterior lies an intricate web of engineering mastery. You see, as vehicles become lighter to boost fuel efficiency and reduce emissions, maintaining their structural integrity becomes crucial to ensure safety and performance don’t take a nosedive.

Read Now : Quattroporte Infotainment System Updates

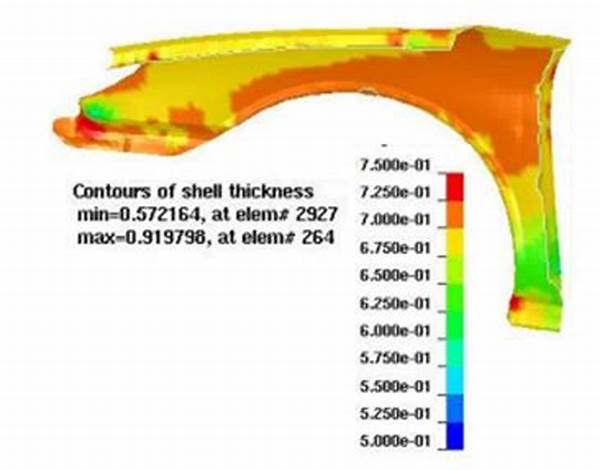

To get technical about it, lightweight vehicles often use advanced materials like carbon fiber, aluminum, and high-strength steel to construct their frames. These materials contribute to a lighter weight but come with unique challenges in terms of maintaining strength and stability, especially under stress. The architects behind these innovations bend over backward to ensure that despite their reduced heft, these vehicles remain robust against impacts, resist deformation, and keep their inner workings well protected.

Achieving structural integrity in lightweight vehicles is like a tightrope walk. Engineers have to balance between minimizing weight and maximizing safety. They’re continuously pushing boundaries and leveraging cutting-edge technologies to guarantee that these vehicles can potentially offer the same, if not better, safety standards compared to their heavier counterparts. It’s all about blending the art of design with the science of engineering to deliver both safety and efficiency on the road.

Challenges in Ensuring Structural Integrity in Lightweight Vehicles

1. Material Selection: Picking the right materials is key to maintaining structural integrity in lightweight vehicles. The balance between weight and strength must be spot on.

2. Cost Challenges: Building lightweight rides ain’t cheap, bro. These top-tier materials and tech can rack up the bucks.

3. Manufacturing Techniques: Crafting these masterpieces requires some fancy production tech, which is totally epic but kind of complex.

4. Durability Concerns: With reduced mass, keeping these babies rugged over the long haul is crucial, ’cause no one likes a car that falls apart.

5. Safety Standards: Meeting safety standards while keeping things light needs some serious wizardry, Intel from the past is not enough.

Innovations Promoting Structural Integrity in Lightweight Vehicles

When it comes to structural integrity in lightweight vehicles, engineers are continuously pushing the envelope. They’re using high-strength, low-weight materials and clever designs to keep your ride both secure and svelte. Imagine cruising in a sleek car built with space-age materials; lightweight, yet tough as nails. That’s the vibe they’re going for!

In the world of lightweight automobiles, they’re hustling hard to ensure that everything checks out in the safety department. The drive for innovation is real, with specialists geeking out over computer simulations and crash test data. They’re forever tweaking and perfecting the balance between lightness and strength so that we can hit the road with confidence, knowing that our cars will hold it together, even in tight spots.

This adventure isn’t just about ditching extra mass for the sake of speed or eco-friendliness. Nah, it’s about crafting a masterpiece on wheels that defies expectations. Thanks to the relentless grind towards enhancing structural integrity in lightweight vehicles, we can look forward to a future with rides that are not only efficient but also wicked safe and oh-so-cool.

The Future of Structural Integrity in Lightweight Vehicles

1. Hybrid Materials: Mixing materials for the perfect combo of lightness and strength is gonna be the future for structural integrity in lightweight vehicles.

2. Advanced Simulations: Virtual reality’s playin’ a massive role, bro, predicting and enhancing vehicle performance before a single piece of metal’s bent.

3. Smart Manufacturing: Robotics and AI are teaming up to make sure every piece is right on the money, no slack here in structural integrity in lightweight vehicles.

4. Sustainability Goals: Eco-friendly production processes are all the rage, offering cars that are green and mean on the streets.

Read Now : “legroom In Subaru Outback Seats”

5. Driver Safety Tech: Next-gen tech ensures if things go sideways, your ride won’t. Safety features are getting flashier and way more legit.

6. Custom Design: Tailored designs for enhanced durability give your ride a new level of personalization without sacrificing integrity, that’s the ticket.

7. Rapid Prototyping: When you can whip up designs in a heartbeat, it’s game on for testing and refining structural integrity in lightweight vehicles.

8. Regulatory Synergy: Harmonizing global standards to make sure everything stays on point for international rides.

9. Energy Absorption: Innovations in absorbing crash energy ensure optimal protection with sleek designs untouched.

10. Collaborative Ecosystems: Sharing knowledge globally helps keep everyone in the loop with the latest in structural advances.

Evolution and Impact of Structural Integrity in Lightweight Vehicles

The game of ensuring structural integrity in lightweight vehicles is ever-evolving. It’s like this huge puzzle that engineers are constantly figuring out, piece by piece. Imagine creating a car that’s feather-light but when it’s go-time, holds its ground like a champ. That’s the revolution in the automotive industry. Lightweight materials are not just a trend; they are a full-blown movement with serious implications. As these materials become more mainstream, manufacturers are all about that innovation life, experimenting with new methods to keep these light rides safe and sound.

The benefits? Oh, they’re massive. The push for structural integrity in lightweight vehicles means better gas mileage, lower emissions, and a smaller carbon footprint. But hey, it’s not only about the environment; it’s about performance and safety too. These vehicles are crafted to be agile yet sturdy, capable of standing the test of time and wear. The evolution is all about combining creativity in design with innovation in engineering, producing cars that drive smoother, last longer, and look cooler.

In short, the structural integrity in lightweight vehicles isn’t just some buzzword. It’s the heart and soul of the modern car industry, quietly working behind the scenes to ensure that every ride is better than the last. With today’s tech and tomorrow’s potential, the future looks pretty rad.

Pros and Cons of Structural Integrity in Lightweight Vehicles

Standing on the cutting edge, structural integrity in lightweight vehicles isn’t all sunshine and rainbows; it’s got its pros and cons, for sure. On one hand, you’ve got fuel efficiency and swag with sleek designs that optimize performance like no other. The perks? They’re major. Big wins in terms of fuel mileage and reduced emissions twist the arm for eco-friendliness. But hold up, there’s more—better agility and handling give a serious nod to driving confidence and fun.

On the flip side, crafting these bad boys requires spending big bucks. Materials and methods that ensure robust structural integrity in lightweight vehicles can pinch your wallet and make production time-consuming—no sugar-coating it. Not to mention, the ongoing battle to meet safety metrics while staying lightweight is no easy feat, leaving some wondering if it’s worth the hassle.

In summary, while the ride’s smoother with lightweight swag, the path there involves high-tech challenges and economic considerations that keep engineers on their toes. It’s a balancing act in the world of automotive engineering, ensuring that every vehicle is as safe as it is advanced.